The shape of a container is the result of a complex series of relations that are established between the materials it is made of and the materials of the contents, brought together to accomplish a specific function (contain, preserve, obtain, pour...) not separate from the importance of aesthetic order.

But not only, the material in its requirement to be serially modelled into the shape of a product, is also characterised by specific technologies or production processes, able to shape it according to determined rules.

It is the task of the designer to master these processes and through the design process, to know how to meet the various requirements by designing a product that can be launched onto the market with competitiveness.

Cup Cap, Antonella Paparella, Veronica Piazza. Din, Giulia Cavinato, Elisabetta Ferraro

Cup Cap, Antonella Paparella, Veronica Piazza. Din, Giulia Cavinato, Elisabetta Ferraro Flora, Alexandra Zanasi, Alberto Zuccoli. Foggy, Nicholas Gamberini, Luca Tarozzi

Flora, Alexandra Zanasi, Alberto Zuccoli. Foggy, Nicholas Gamberini, Luca Tarozzi Square Colander, clara Panin. Sucre, Francesca Bonaccorsi

Square Colander, clara Panin. Sucre, Francesca Bonaccorsi Shade, Chiara Cavalieri. soaPOPera, Michela De Tomi

Shade, Chiara Cavalieri. soaPOPera, Michela De Tomi Mollettao, Giulia Bigotto. Mono, Stefania Corradetti, Francesco Del Fuoco

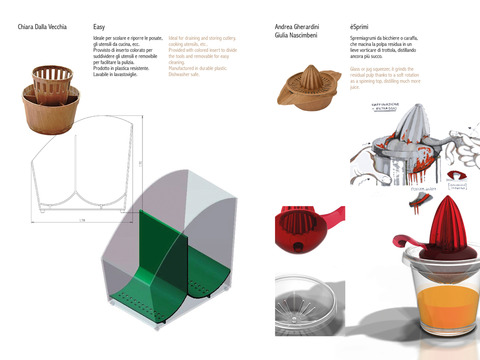

Mollettao, Giulia Bigotto. Mono, Stefania Corradetti, Francesco Del Fuoco Easy, Chiara Dalla Vecchia. èSprimi, Andrea Gherardini, Giulia Nascimbeni

Easy, Chiara Dalla Vecchia. èSprimi, Andrea Gherardini, Giulia Nascimbeni

The decision to focus Product Technologies Workshop II, academic year 2011-2012, on the design of containers for domestic use, originated from the intention to place the student in front of the design of a concrete object, which can be related to a daily reality and be hypothetically manufactured by local companies. This theme thus allowed effective dialogue between the reality of university and that of production. Despite appearances, the design of a commonly used object is not at all simple; its functionality is constricting and forces the designer to meet ergonomic requirements and to analyse the parts of the human body coming into contact with the product - such as the hands and the mouth - with which countless movements are made every day. This is not always a simple and enjoyable process.

As these commercial objects are easily found and identified, thanks to widespread and low cost production, the student was able to identify him/herself with the user and to study the product by directly examining its performance.

By observing and analysing physical objects, first through touch, then through manual and technical design, and finally through the creation of an accurate three dimensional cardboard reproduction, the student aimed to point out various aspects of the product that could potentially be improved and then to highlight them in the project through innovative elements: the subject and final objective of the course.

Knowledge of the production systems described in the classroom and then included in focused visits to companies in the sector made the design possible according to feasibility criteria.

The designs, in the intermediate phase of the project, were checked by the VE.CA. management, a company backing the course, which commented and gave indications on the economic and commercial aspects of the products put forward, as well as technical evaluations. All this directed the student towards a carefully planned activity on the real requirements of the project, in which the creative contribution, if adequately meeting the requirements of industrial production and economic dynamics, can be materialised into tangible values.

Raffaello Galiotto

Previous Post-it

back to top print

Post-it

ISSN 2239-6063

edited by

Alfonso Acocella

redazione materialdesign@unife.it